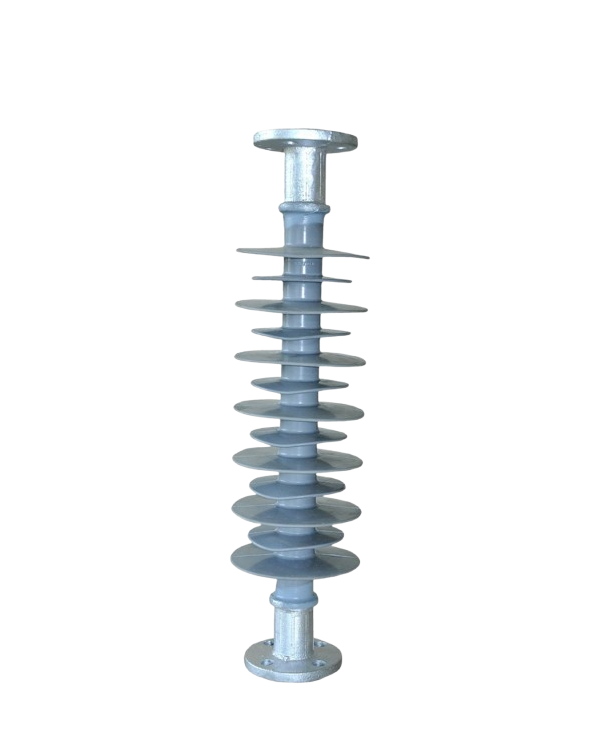

Composite Polymer Insulators

At Venkateswara Suppliers Pvt. Ltd. (VSPL), we specialize in designing and manufacturing high-quality Composite Polymer Insulators for modern power distribution and transmission systems across India.

Engineered with FRP cores, silicone rubber housing, and precision metal fittings, our polymer insulators ensure superior mechanical strength, pollution resistance, and long-term reliability — truly living up to our promise of being Safe. Strong. Durable.

What Are Composite Polymer Insulators?

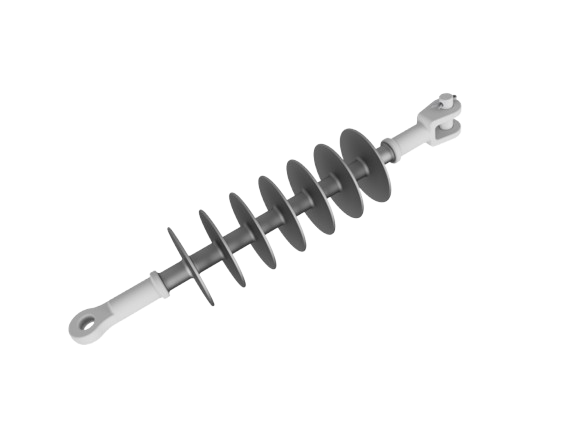

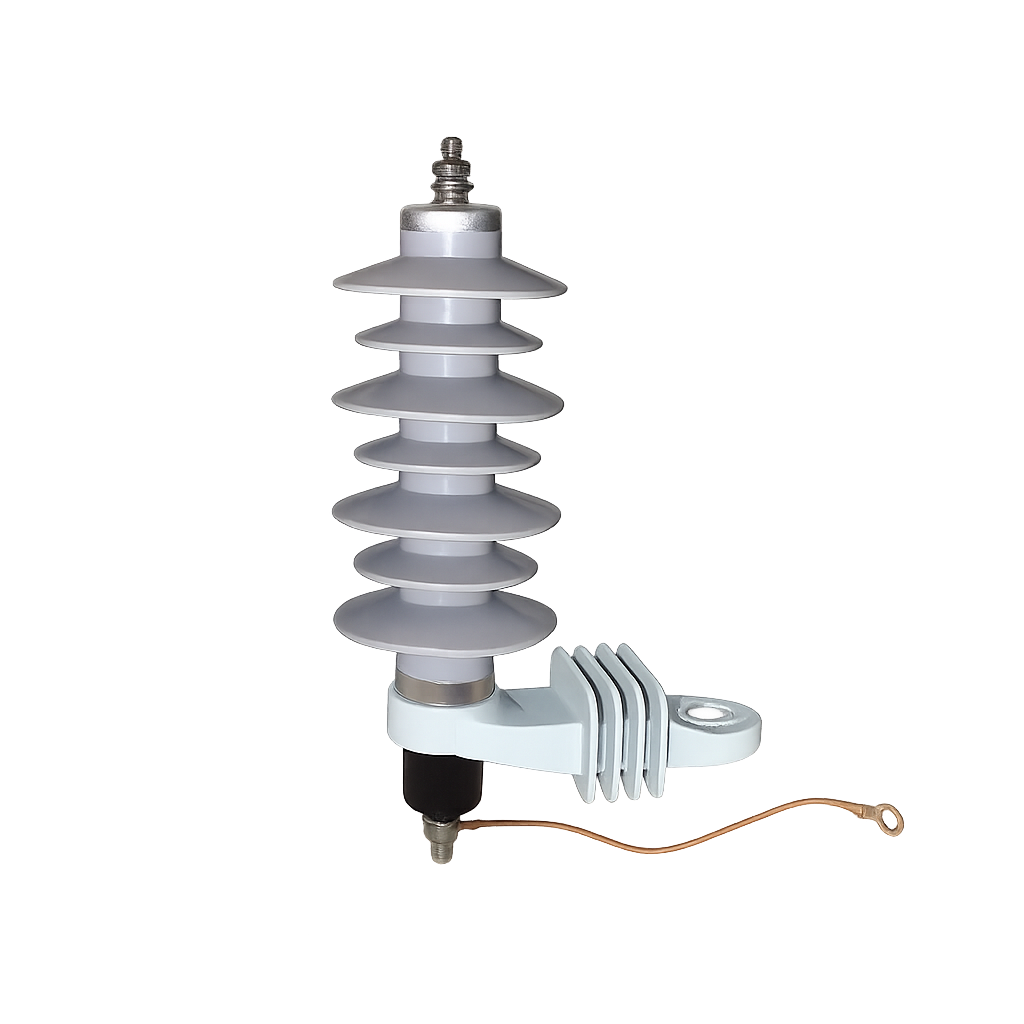

Composite Polymer Insulators (also known as Silicone Rubber Insulators) are advanced electrical components made using a fiberglass-reinforced plastic (FRP) rod, silicone polymer sheath, and galvanized metal fittings.

They replace traditional porcelain or glass insulators with lightweight, non-brittle, and corrosion-resistant alternatives suitable for harsh Indian climates.

Advantages at a glance

Suitable for polluted and harsh environments

Resistance to breakage and vandalism

Superior tracking and erosion resistance

Resistance to earthquake

Low leakage current

Environment friendly process of manufacture

Good mechanical and electrical characteristics

Light in weight - handling and transportation advantage

Easy to install and maintenance free

Excellent hydrophobicity, hence no need to clean

Products

Why Choose VSPL Composite Polymer Insulators

With over 25 years of electrical manufacturing experience, Venkateswara Suppliers Pvt. Ltd. delivers polymer insulators that meet IEC 61109, IEC 62217, and ANSI C29.13 international standards.

Our advanced Palakkad facility features in-house FRP pultrusion, HTV & LSR silicone moulding, and automated quality testing up to 200 kV.

Key Benefits:

Salient Features

VSPL insulators have qualified in 5000 hours Accelerated Ageing test as per IEC: 62217.

VSPL insulators have qualified in 1000 hours Tracking and Erosion test as per IEC: 62217.

Use of both HTV and LSR grades of silicone rubber depending upon the requirement of the product.

FRP rods are manufactured in-house using ECR grade Glass Fiber and Hydrolysis Resistant Epoxy Resin System.

The VSPL make composite silicone rubber insulators meet the requirements of IEC: 61109, IEC 62217, IEC: 60815, IEC: 62231, IEC: 61462, ANSI C29.13 and any relevant international standards.

Robust packing for easy handling, transportation and site storage.

Test Facilities

Our state-of-the-art testing laboratory ensures every product meets international quality standards

Silicon Rubber

- Tensile Strength

- Percentage Elongation

- Tear Strength

- Specific Gravity

- Hardness (Shore A)

- Inclined Plane Tracking & Erosion Test as per IEC:60587

- Moulding Machine for Making Rubber Sheets

FRP

- Dry Penetration

- Water Diffusion

- Percentage of glass content

- Water Absorption

- Brittle Fracture Resistance

- Bending Load Test

- Specific gravity

Metal Fittings

- Uniformity of Zinc coating

- Mass of Zinc coating

Insulators

- Non-Destructive Testing for bonding in the insulator

- Ultrasonic Crack Detection During Crimping

- Horizontal tensile test machine for test on long rod insulator including routine testing

- Bending test machine for Post and Railway Insulators

- High Voltage test up to 200kv

- Assembled core load-time test on all types of long rod insulators

FAQs

We offer 11 kV, 15 kV, 22 kV and 33 kV pin insulators for distribution lines.

Yes — they offer higher impact strength and resist breakage during transport or installation.

No. Their silicone rubber housing is hydrophobic and self-cleaning, ideal for dusty or humid zones.

Yes. Each unit undergoes routine mechanical, electrical and ageing tests before dispatch.

Absolutely — our Palakkad facility develops custom moulds and fittings within short lead times.

Get a Quote

Contact us today to learn more about VSPL's Composite Polymer Insulators, including product details, pricing, and custom solutions.

Business Hours

Mon - Sat: 9:00 AM - 6:00 PM